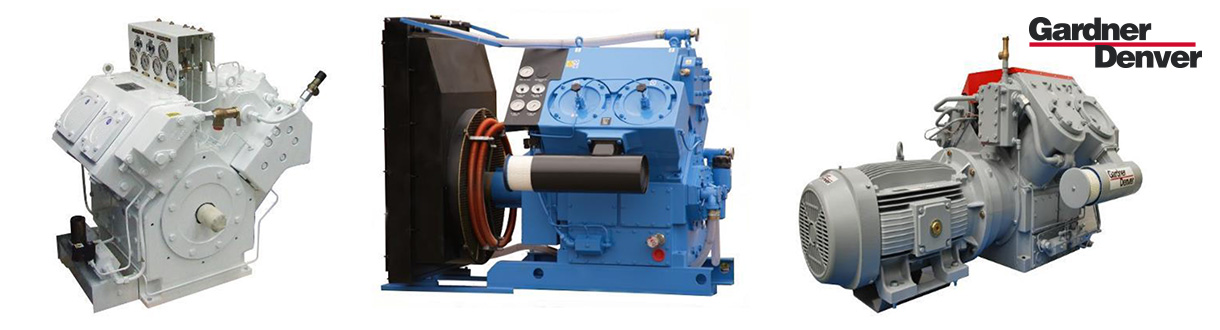

Reavell

The Reavell compressors from Gardner Denver offer a compact design which limits installation costs. The compressors feature anti-vibration mounts that eliminate the need for a special base or foundation.

The foundation simply needs to be level and able to support the static weight of the compressor.

Optimal Serviceability.

The unrivaled design of Reavell air-cooled units provide convenient access when it comes to servicing the units with items such as: liners, valves, pistons, rings and spin-on oil filters. All maintenance parts are removable without a major teardown which equals more uptime.

Application Flexibility.

Reavell air-cooled compressors are manufactured to withstand some of the harshest compression applications across the globe. Typical applications include engine starting and leak & pressure testing.

Reavell water-cooled compressors are manufactured to withstand some of the harshest compression and boosting applications across the globe.

Typical applications include leak/pressure testing, gas recovery, autoclaves, wind tunnels, compressed natural gas (CNG), engine start and electrical power stations. Gas service consists of nitrogen, helium, hydrogen and methane. Contact Aircom for a complete listing of approved gases.

Air-Cooled Features

- 232 to 725 PSIG

- 3 to 37 CFM FAD

- Direct drive or V-Belt drive, oillubricated two-stage compressor

- Anti-vibration mounts

- Balanced cylinder configurations

- Intake filter silencer with replaceable element

- Inter and after-stage coolers

- Low lift plate valves

- Low piston speed

- Splash lubrication system

- Safety valves on all stages

- Delivery pressure switch and gauge

- Electrically operated unloading / drainage system

- Motor starter and control panel

- High temperature cut-out switches and gauges

- Oil and moisture separators with automatic drainage

Water-Cooled Features

- 145 to 6,000 PSIG

- 16 to 171 CFM FAD

- Direct drive or V-Belt drive, oil-lubricated two to four-stage compressor

- Closed loop cooling systems available

- Cylinders fully enclosed by waterjacket

- Anti-vibration mounts

- 90° V-configuration for excellent balance

- Intake filter silencer with replaceable element

- Inter and after-stage coolers

- Direct valve access for easy maintenance

- Oil and moisture separators with automatic drainage

- Forced lubrication system with oil pump, filter and relief valve

- Corrosion rod in water-jacket

- Final delivery non-return valve

- Water cooling from closed radiator circuit or mains (fresh or sea)

- TEFV electric motor with explosion proof options

- Safety valves on all stages

- High temperature cut-out switches and gauges

- Final delivery air temperature gauge

- Low oil pressure cut-out switch and gauge

- Pressure gauge on each stage

- Controlling air pressure switch

- Bursting disk in water-jacket

- Motor starter and control panel