Liquid ring

The Robuschi RVS Series liquid ring vacuum pumps includes innovative characteristics allowing them to suck in gas and vapours, without contamination from the seal liquid and with nearly isothermal gas compression.

Thanks to its construction features, the liquid ring vacuum pumps are remarkable for low water consumption, low noise and vibrations, reliable service and minimum maintenance. The variety of construction materials allows a wide field of applications. In addition to this, they can also be used as a compressor within the limits shown in the use and maintenance manual.

Impeller

The impeller is fitted with forward curved blades to give the service fluid the energy that is necessary for the compression and the front hub is conical to facilitate the discharge of compressed gasses.

Shaft

The heavy-duty shaft is protected from the contact with the service fluid and conveyed gas, except for the RVS sizes 23 and 25, because they are made of stainless material (see the page Material execution)

Support

RVS 3 to 16/M: impeller fitted directly on the shaft and motor flange.

RVS 3 to 21/SG: cantilever impeller on the support with shielded self-lubricating bearings.

RVS 23 to 25: equipped with two supports with self-lubricating bearings.

RVS 30 to 60: lubrication with external greaser.

Plate

A greater volumetric efficiency is possible thanks to the stainless-steel laser-cut patented distribution plate and to the good layout of the intake and discharge ports.

VGI

Anti-cavitation valve.

Casing

Reduced consumptions, thanks to the efficient layout of the internal intake and delivery gas baffles.

Shaft seal

The RVS 3-25 includes single mechanical seals flushed from the service fluid. The sizes RVS 30-60 can be installed both packing seals flushed from the service fluid or from the outside, both double mechanical seals.

Automatic valve

The automatic valve makes it possible to adopt the compression ratio of the pump at the installation conditions, with less energetic consumption.

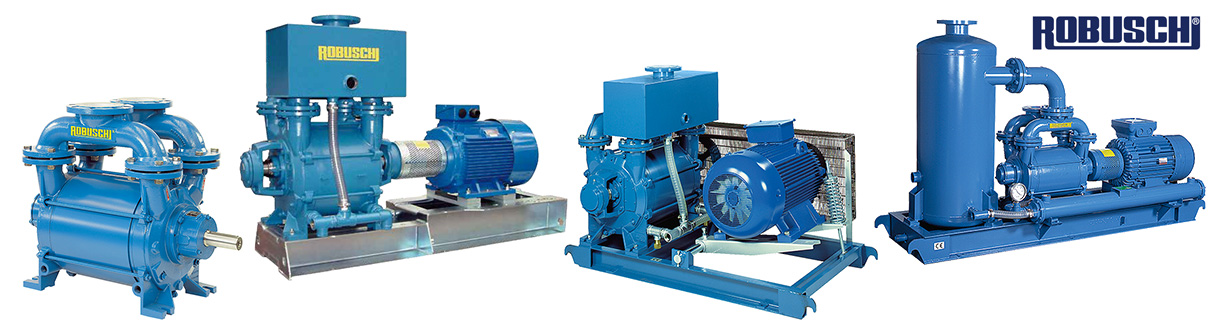

Electropump Units

CRVS

The vacuum compact systems CRVS are equipped with a pump that is already coupled with the electric motor via elastic direct coupling. This ensures a perfect alignment, optimal and long-lasting operation. The CRVS base was specifically designed to guarantee high stiffness and low vibrations.

LRVS

The vacuum compact systems LRVS feature belt and pulley drive, a motor oscillating suspension patented system, which makes it possible to reduce the load on the motor bearings and pump, by keeping constant over time the belts tension. This makes it possible to easily adapt the drive to various motors sizes without modifying the unit’s dimensions.

The V-Belt coupling makes it possible to select the vacuum pump at the optimal speed, ensuring thus, the correct capacity that is necessary to the system, without waste of energy, with capacities of up to 4200 m3/h.

Thanks to the recovery manifold both the CRVS and LRVS units can be supplied with partial recirculation, achieving thus a substantial saving of service water.

Vacuum units

KRVS

The KRVS are units developed for the vacuum generation in the most varied sectors, such as the chemical, petrol-chemical, pharmaceutical, textiles sectors…..and many more…. They consist of liquid ring vacuum pumps of the RVS series with separation tank for the partial recirculation of the service fluid and corresponding connection pipes (/P); in the version with total recirculation (/T) the unit is fitted with a heat exchanger. The separator tank also silences the noise at the pump discharge.

• Vacuum: up to 33 mbar (abs)

• Capacity: up to 4,200 m3/h

The partial recirculation units (/P) are the Robuschi answer for the recovering of most part of the service liquid, which is used to supply the pump. However, it is necessary to provide a minimum supply of fluid in order to prevent overheating of the liquid ring, which would penalize the pump efficiency. Depending on the vacuum degree that you wish to achieve, it is possible to recover up to 70% (for details, please see corresponding table).

The vacuum units KRVS with total recirculation (/T) are especially recommended in case of polluting gasses and /or liquids, with consequent disposal issues. In these cases, it is indeed necessary to supply the pump in closed circuit and cool the fluid by means of the heat exchanger, which prevents the contact between the cooling fluid and the fluid itself. The service fluid temperature can be adjusted by acting on the capacity of the cooling fluid.

Such characteristics ensure low noise and vibrations and extremely simplicity of installation, start-up, adjustment and maintenance.

Robuschi RVS Series

| Model | Motor | Min. Vacuum | Max. Pression | Max. Temperature | Max. Viscosity | Liquid Content 1 | Inertia 2 | Sound Level | Data sheet | Quote request | ||

| rpm | kW | mbar | mbar | gas | liquid | mm2/s | litres | kg m2 | dB (A)±3 | |||

| RVS 3/M | 3420 | 2,2 | 33 | 100 | 100˚C | 70˚C | 8 | 0,25 | 0,004 | 72 | https://www.aircom.ca/b_pdf/Robuschi-vacuum-pumps/Aircom-Robuschi-RVS-Series-Liquid-ring-vacuum-pumps-ANNEX.pdf | https://www.aircom.ca/eng/quote-request/ |

| RVS 7/M | 1750 | 4 | 1,1 | 0,05 | ||||||||

| RVS 7/SG | 200 | |||||||||||

| RVS 14/M | 5,5 | 100 | 1,5 | 0,06 | ||||||||

| RVS 14/SG | 200 | |||||||||||

| RVS 16/M | 7,5 | 100 | 2,3 | 0,11 | ||||||||

| RVS 16/SG | 200 | |||||||||||

| RVS 17/SG | 11 | 3 | 0,15 | |||||||||

| RVS 21/SG | 15 | 4 | 0,23 | |||||||||

| RVS 23/CT | 18,5 | 20 | 6 | 0,33 | 74 | |||||||

| RVS 25/CT | 30 | 8 | 0,51 | 76 | ||||||||

| RVS 30/CT | 1170 | 37 | 300 | 15 | 2,16 | 78 | ||||||

| RVS 40/CT | 55 | 24 | 3,33 | 79 | ||||||||

| RVS 60/CT | 888 | 127 | 95 | 8,5 | 82 |

1 Liquid content in the pump up to the level of the shaft

2 Moment of inertia of rotating parts

Although we have made every effort to provide current and accurate information on this site,

we cannot guarantee that all information is error proof.

Should any information be critical, please communicate with one of our technical sales representatives.