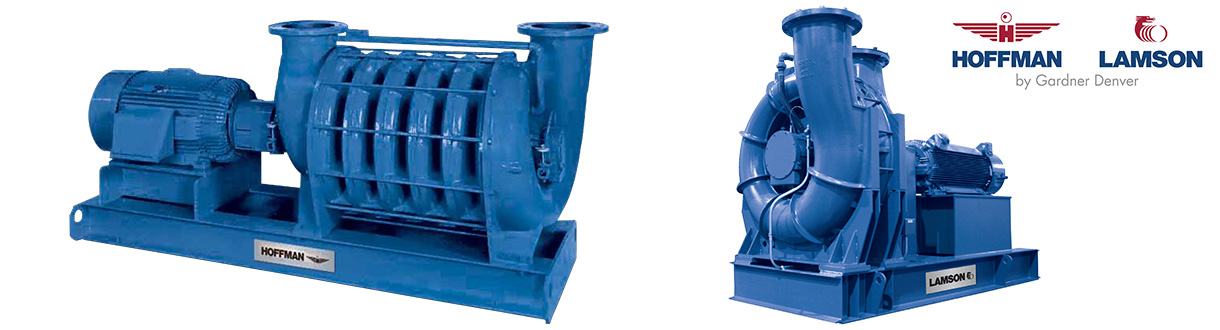

Lamson Hoffman

Hoffman® & Lamson® brand multistage centrifugal blowers are recognized around the world as the best blower and exhauster solutions for wastewater treatment and other aeration applications. For more than 100 years customers have trusted the quality performance these legacies provide. Anchored in tradition, this experienced Hoffman & Lamson blower/exhauster lineup remains the most comprehensive offering in the world.

Today, as the largest manufacturer of blowers/exhausters, our number one priority continues to be unparalleled responsiveness to meeting customer needs. Our unwavering commitment to developing long-term customer relationships, innovative product designs, and quality manufacturing is evident with over 200,000 units manufactured. We are continually improving delivery and response times while setting the highest performance standards in the industry.

For the efficient, reliable performance you expect and your operation demands, you need HOFFMAN & LAMSON.

Serving a Wide Range of Applications

The range of applications for Hoffman and Lamson centrifugal products is ever-expanding and is firmly illustrated with over 100,000 machines in operation. The experienced HOFFMAN & LAMSON team, backed by years of research and development, provides effective, affordable solutions for a variety of application needs.

Water & Wastewater Treatment

In water & wastewater treatment, air is provided to water and wastewater aeration systems and air scouring/filter backwashing. Hoffman and Lamson blowers can be specified for coarse/fine bubble diffuser systems, reactor batch supplemental air, digester gas boosters, grit channels and sludge digestion applications

Industrial Processing

In the industrial market, our blowers provide air or gas for sulfur recovery, combustion air, process gas boosting, coal mine venting, fluidized bed combustion systems, vapor and gas extraction, composting, sludge incineration and printing systems, to name a few

Engineered Vacuum Systems

HOFFMAN & LAMSON Engineered Vacuum Systems are used to pick up, convey and capture a myriad of materials ranging from aluminum granules to corn flakes.

SUPERIOR QUALITY

In Design, Materials, and Workmanship

Durable, reliable and efficient, HOFFMAN® & LAMSON® centrifugal blowers/exhausters represent the highest quality workmanship in the industry using the finest materials and state-of-the-art machining tools available today. Our dedication to design and quality assures you that the HOFFMAN & LAMSON blower you select is the best in the industry.

Multiple Baffle Rings

Many models feature our patented Multiple Baffle Rings (MBR™) which help turn airflow smoothly into the eye of the impeller, dramatically reducing inlet passage losses. MBR combined with the two-dimensional impeller design increases blower efficiency and pressure/vacuum capability.

Balance Piston

A balance piston is located at the outlet end of the rotating impeller assembly to compensate for the axial force of the impellers on the inlet bearing. This greatly increases bearing life for longer, trouble-free operation.

Multistage Shrouded Impellers

Two-dimensional shrouded cast aluminum impellers are balanced individually and keyed onto the shaft. On most blowers, the complete assembly is then balanced to achieve smooth operation with lowest vibration levels in the industry. Rotor assemblies are designed to operate well below first critical speeds for added reliability.

Flexible Coupling

Blowers/exhausters connect directly to the power source with a precision aligned flexible coupling. This optimizes power transfer and minimizes bearing loads for longer

Cast Housing

Blower housings are precision machined from high-grade cast iron. Smaller models are cast aluminum. The intermediate blower sections are assembled using high strength steel tie rods. The blower and its driver are mounted together on a single steel baseplate. This assures long lasting performance and durability.

Labyrinth Seal

Non-contact, non-wearing labyrinth air seals are standard. This no-maintenance seal is used in most air and some gas applications (purge option available). Carbon Ring seal for special air and gas applications requiring superior sealing, optional carbon ring seals are available with purge option.

Carbon Ring Seal

For special air and gas applications requiring superior sealing, optional carbon ring seals are available with purge option.

MAX Seal (Mechanical Axial)

An innovation in dry seal technology, the MAX Seal reduces fugitive emissions by up to 67% when com-pared to traditional seal options. Ideal for landfill gas and applications handling toxic and explosive gases. Improves the safety of your operation while extending bearing life and lowering total

PERFORMANCE & SPECIFICATIONS

Models to 41,000 cfm

HOFFMAN & LAMSON multistage centrifugal blower/exhauster models cover a broad performance range to meet our needs. Each base model presents its own unique performance characteristics and design features that are illustrated in the chart below and the air maps on the following pages.

60 Hz & 50 Hz models available

Our 900 series is the first line of multistage centrifugal blowers with a true 50Hz design. The optimized design offers up to 8% higher efficiency and high pressure capabilities when compared to 60Hz blowers that are modified for 50Hz operation.

CFSelect+ precision sizing service

To help customers select the optimal blower or exhauster for their operation, HOFFMAN & LAMSON engineers use CF Select, a computerized sizing service. CF Select software can create an infinite number of performance curves for pressure, efficiency, temperature and power consumption. Based on the specific gas mixture, inlet conditions, flow and pressure/vacuum requirements, CF Select chooses the most appropriate model, impeller design, operating speeds or throttling options

Choose from multiple drive options

HOFFMAN & LAMSON blowers and exhausters may be direct driven, V-belt driven or gearbox driven with an electric motor. Alternative drivers include steam turbines, diesel engines, gasoline engines and liquid petroleum or methane gas engines. Also available is the Rigel Controls system. Rigel Controls automatically adjusts airflow output to match the actual airflow demand. The blower/exhauster power requirement adjusts automatically resulting in energy savings. Your representative can work with you to determine the best drive option and configuration to match your application.

Size & Performance to Fit Your Application

With 22 models to choose from and the ability to specify a variety of manufacturing options, you can be assured that the blower or exhauster you order will deliver the performance you expect. In addition to the base models available, customers can choose from a variety of design options such as special coatings, alternative component materials, oil or grease lubrication, special seals, drive couplings and power sources. The HOFFMAN & LAMSON blower/exhauster you specify is then manufactured according to your unique application and requirements.

Performance Tested

Hoffman and Lamson blowers and exhausters are tested in our state-of-the-art test labs in our global manufacturing and assembly plants. Using the most sophisticated testing equipment available in the industry, we test units up to 3,000 horsepower in accordance with the latest edition of the ASME test code PTC-10, ISO and all other applicable international standards at our Bentleyville, Pennsylvania plant. Units are brought into this two-story laboratory and connected to a specialized power unit and precision monitoring equipment. The blower/exhauster is then tested and evaluated for performance characteristics, noise level, and vibration. Overall performance data is captured in real time for performance curve evaluation and documentation. We frequently host performance testing for customers and inspectors from all over the world.

Applications

- Aeration Basins

- Air Drying

- Air Flotation and Sliding

- Air Knife Stripping

- Blow-off Systems

- Carbon Black

- Coal Gasification

- Combustion Air Blowers

- FGD – Forced Oxidation

- Fluidized Bed

- Gas Boosting

- Gas Recovery

- Landfill Gas

- LNG Vaporizers

- Printing Operations

- Pulp Dewatering

- Steel Plating Baths

- Sulfur Recovery

- Vapor Recompression

- Aeration

- Aerobic Digestion

- Biogas

- Digester Gas Boosters

- Filter Backwashing/

- Air Scouring

- Grit Chambers

- Clean Rooms

- Electronics

- Explosive Dust

- Collection

- Flux Recovery

- Housekeeping

- Nuisance Dust Collection

- Oral Evacuation

- OSHA Standard Required

- Pneumatic Conveying

- Powder Paint

- Product Reclamation

- Sanitary/Product Quality

- Source Capture