Belliss & Morcom

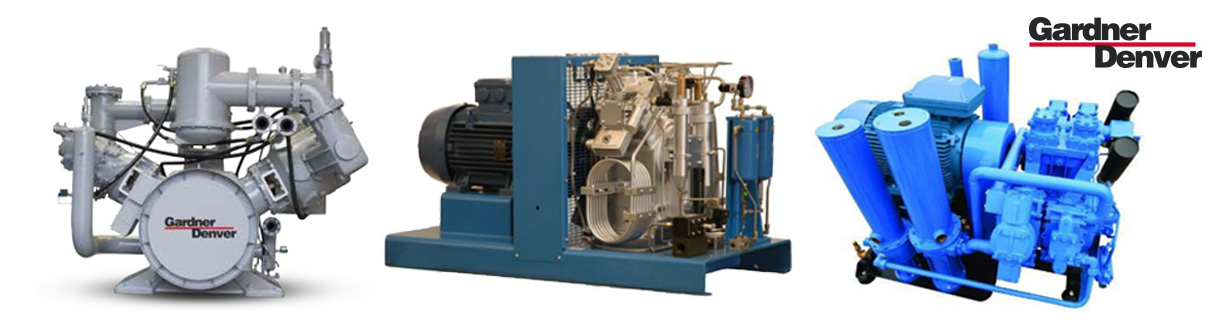

The highly engineered products in this Belliss & Morcom reciprocating air compressor has set the new standard for productivity at low operating costs.

This industrial air compressor is water cooled, making it oil free. A fully balanced operation compounded with a variable speed drive makes this machine one of the most versatile products on the PET bottle blowing market.

GD Belliss & Morcom oil free direct drive reciprocating compressors for PET bottle blowing are designed to ensure decades of reliable operation in all operating environments.

We have over 40 years of experience in supplying oil-free reciprocating compressors for the PET bottle blowing market and have supplied compressors for some of the largest PET bottling plants in the world today.

Due to our vast experience, Belliss & Morcom have become the recogized industry leaders, where customers globally enjoy greater productivity and lower operating costs. Belliss & Morcom compressors set the standard for reliable, efficient and cost-effective PET bottle blowing operations.

Features

The Belliss & Morcom VH range of compressors offers a neatly arranged compressor system which provides maximum oil-free air capactiy in the smallest available footprint.

- 420 to 1,500 m3/hour at 40 barg

- 90 to 260 kW direct zero drive loss ‘shaftless’ motor

- Oil-free

- Water cooled

- 3 stages

- Capacity control – 0 to 100%

- Variable speed drive range from 50-100%

- Fully balanced operation

The Belliss & Morcom WH range of compressors offers higher volumes of oil-free air utilizing energy efficient equipment and components. The double acting design provides greater flexibility in capacity control and lower power consumption.

- 1,680 to 3,200 m3/hour at 40 barg

- 280 to 550 kW direct zero drive loss ‘shaftless’ motor

- Oil-free

- Water cooled

- 3 stages

- Capacity control – 0% / 50% / 100%

- Variable speed drive range from 30-100%

- Fully balanced operation

Benefits

Gardner Denver Belliss & Morcom have the ability to understand our customer’s specific requirements and are committed to ensuring we provide intelligent solutions that meet your ultimate needs.

Lowest Cost of Ownership

- With the highest efficiency motors at 97.1% and the latest in extended life materials technology, both the VH & WH range continue to outperform all other 40 barg oil-free compressors in the PET industry. Maintenance costs are also kept to a minimum due to our unique shaftless motor, with no belts or bearings there are fewer parts to maintain, which can eliminate unscheduled downtime.

Low Power Consumption – High on Efficiency

- With each compressor driven by our EEF compliant water cooled motor, our 3 stage oil-free compressor is proven to be the most power efficient design concept for a 40 barg PET compressor.

Small Compressor Footprint

- Where space is at a premium, the Belliss & Morcom range of oil-free compressors offer a neatly arranged compressor system in the smallest footprint available. With no specialist foundations required, our compressor systems are easily installed and fully operational in the shortest possible time scale.

Balanced Operation

- All Belliss & Morcom compressors are dynamically balanced, therefore removing the need for any special and expensive structural foundations. The compressor room floor is only required to carry the static weight of the compressor.

Maximum Oil-Free Air Quality

- With absolutely no risk of contamination, Belliss & Morcom compression technology delivers the highest quality oil-free compressed air meaning no possibility of oil contamination in your process up to ISO 8573 class 0. The intrinsically oil-free air produced by a Belliss & Morcom compressor meets all air quality standards including Pure Air – ISO 8573-1.